System calculations vs. single component calculations

Two different types of calculations are available to the user in the FVA-Workbench. In the system calculation, the gearbox is considered as a whole, and the effects of the deformation of the machine elements on each other are taken into account. The forces, displacements, etc. that occur are automatically passed on to the individual machine elements.

In the single component calculations, an individual machine element is calculated independently of the rest of the gearbox. The relevant forces, displacements, etc. must be specified individually.

System calculation

The system calculation calculates the power flow and deformations of the entire gearbox. The forces and displacements are automatically passed on to the individual machine elements. Thus, the deformation cross influences are considered in further load capacity calculations. The stiffness and deformation behavior are calculated for all machine elements:

Shafts, plain and rolling bearings, shaft-hub connections, couplings

Cylindrical, bevel, crossed helical, and worm stages

Gearbox casing, planet carriers

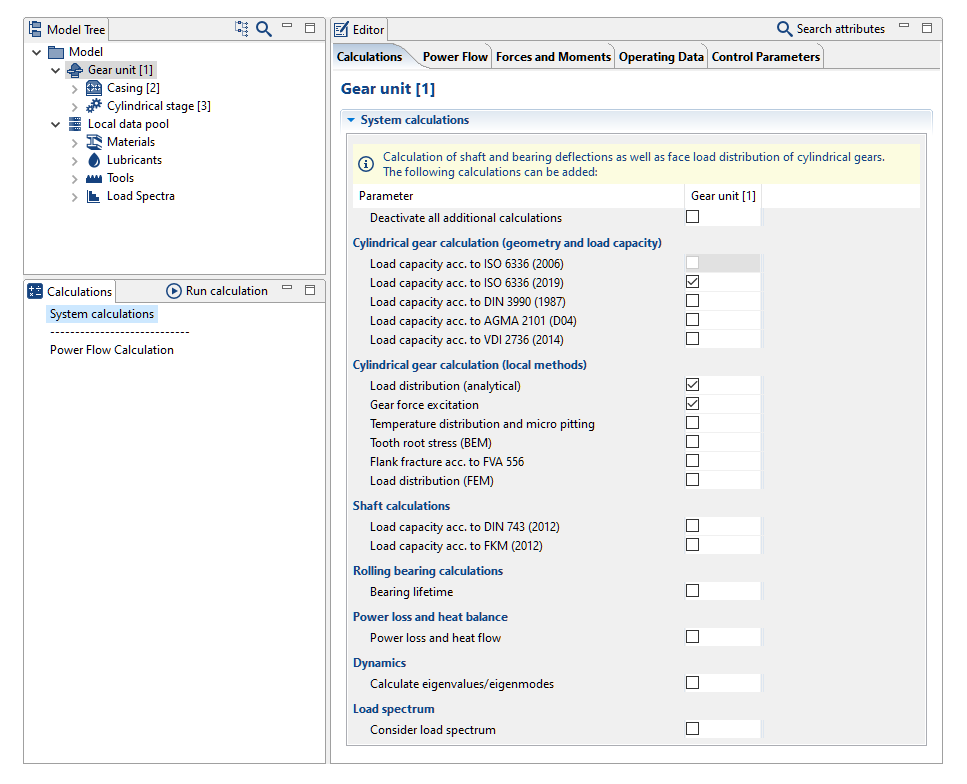

Various other calculations can be performed as part of the system calculation, such as cylindrical gear load carrying capacity, bearing lifetime, or shaft load capacity calculations. Forces, displacements, etc. that have already been calculated are considered in the calculation.

Representation of the total system deformation in the FVA-Workbench 3D Model.

Double-click on the "system calculation" objective under the "calculations" view to start the calculation. Additional calculations can be activated under the "calculations" tab of the gear unit component in the Model Tree.

Single component calculations

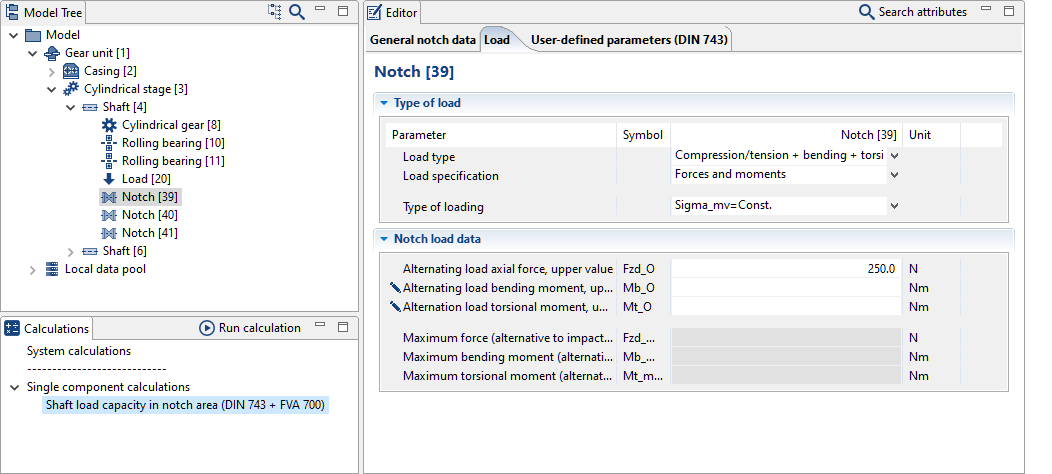

For single component calculations, an individual machine element is calculated without its environment. Forces, displacements, etc. must be specified individually. Cross-influences from the gearbox environment are not taken into account.

A component must be selected in the Model Tree to start a single component calculation. Double-click on an objective under the "calculations" view to start the calculation.