- KnowledgeBase

- General

- Messages

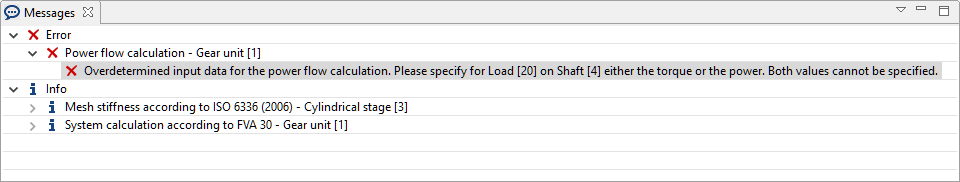

Messages

Information on the current calculation is shown in the messages view of the FVA-Workbench.

System calculations

Message: “Inconsistent input data. The diameter of the shaft intersects the tooth. Modify the shaft diameter under the gear." |

For cylindrical gears, the wheel body is automatically modeled as a beam element in the system calculation. For external gears, the outer diameter of the shaft is used as the inner diameter of the wheel body, and a virtual diameter calculated from the gear data is used as the outer diameter of the wheel body. The same applies to internal gears. In earlier versions it was necessary to explicitly map the modeling of the wheel body in the shaft contour. This is still possible, but the shaft diameter may not intersect the tooth. For example, for external gears, the shaft outer diameter for the gear must be smaller than the root circle of the tooth. |

Message: "Unable to solve the mechanical system. Check whether the model is statically determined. In particular check axial force absorption of bearings. If necessary, contact technical support." |

The mechanical system could not be solved. In most cases, this is due to a lack of mechanical determination of the system. Check the errors and warnings in the messages window first. Pay particular attention to information about shafts that are not axially fixed or whose tilting degree of freedom is not determined. If necessary, it may be helpful to reduce the complexity of the model by replacing bearings with (linear) stiffness. To do this, set the switch for "bearing input type" to "bearing stiffness." |

Message: "Iteration is not converged. Maximum number of steps reached." |

The iteration procedure for solving the mechanical system did not converge in the permitted number of calculation steps. If not already done, the "Less restrictive termination tolerance for system calculation" switch can be activated under the "control parameters" tab of the gear unit. You can follow the iteration process during the system calculation in the console window of the Workbench. If this still does not help, the problem is usually a bearing with an incorrect load. Check the errors and warnings in the messages window. If necessary, it may be helpful to reduce the complexity of the model by replacing the problematic bearing with a (linear) stiffness. To do this, set the switch for "bearing input type" to "bearing stiffness." |

Message: "This component is likely responsible for the failure of the system calculation iteration (degree of freedom: XY). Check the inputs" |

See "Iteration is not converged. Maximum number of steps reached." In particular, verify that the bearing can bear loads in the specified degree of freedom. |

Message: "The calculation was stopped, as no further improvements were made and the termination tolerance is almost reached. Verify that the accuracy of the results is satisfactory." |

The iteration procedure for solving the mechanical system was ended, as the termination tolerance was almost reached and no further improvements could be made. You can follow the iteration process during the system calculation in the console window of the Workbench. |

Message: "Consideration of gravity was activated. Please note that the automatic consideration of the gravitational force is currently not possible for FE components!" |

See Gravitational influence for FEM planet carriers for a detailed description and possible workarounds.Gravitational influence for FEM planet carriers |

Updating models

Message: "For the following attributes both a value was entered and a list entry was selected. To correct this overdetermination, only the selected list entry was kept." |

This may occur when loading older FVA-Workbench models. Under certain circumstances, the state of combo attributes may be overdetermined. To avoid inconsistent states, only the selected list entry in the model is used. Attribute values that are not used are logged in the fvaworkbench.log file in the installation directory/workspace/.metadata folder. |