Calculations in scripting

The runCalcMethod(methodID, compID); function is used to start calculations in scripting. As parameters, the function requires the ID of the calculation of the method and the ID of the component to be calculated.

System calculations are always performed for the component type "gear_unit". The ID of the calculation method is always "001_SYSTEM_CALCULATION". To add additional calculations to the system calculation, the corresponding calculation attributes must be set to true.

For individual component calculations the calculations are always performed for the respective component. There are different calculation methods available for each component type.

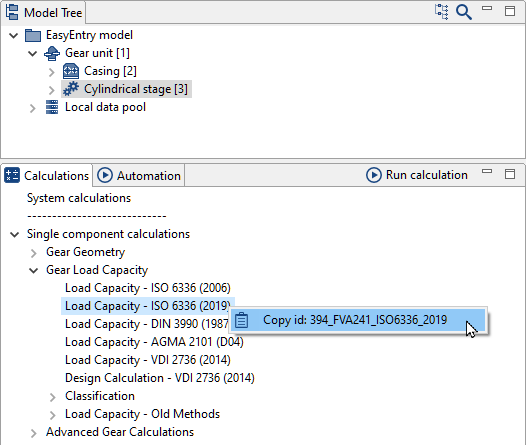

By right-clicking on a calculation, the associated ID can be copied to the clipboard and pasted into the script.

System calculations

Example: System calculation with activated load capacity calculation according to ISO 6336

1var gearUnitID = 1; 2setAttr("gta_switch_iso_6336_2006", gearUnitID, true, EDAT); 3runCalcMethod("001_SYSTEM_CALCULATION", gearUnitID);

Assigns the variable GearUnitID with the ID of the component "gear unit" (Tip: the ID of the gear unit is always 1). | |

Sets the attribute for the "load capacity according to ISO 6336 (2006)" calculation switch to true. | |

Runs the system calculation. |

Cylindrical gear stage

Calculation | Attribute |

|---|---|

Load carrying capacity according to ISO 6336 (2006) | gta_switch_iso_6336_2006 |

Load carrying capacity according to ISO 6336 (2019) | gta_switch_iso_6336_2019 |

Load carrying capacity according to DIN 3990 (1987) | gta_switch_din_3990_1987 |

Load carrying capacity according to AGMA 2101 (D04) | gta_switch_agma_2101_d04 |

Load carrying capacity according to VDI 2736 (2014) | gta_switch_vdi_2736_2014 |

Load distribution (analytical) | gta_switch_3d_load_distribution_analytical |

Gear excitation | gta_switch_3d_force_excitation |

Temperature distribution and micropitting | gta_switch_3d_micro_pitting |

Tooth root stress (BEM) | gta_switch_3d_root_stress |

Flank fracture according to FVA 556 | gta_switch_3d_flank_fracture |

Load distribution (FEM) | gta_switch_3d_load_distribution_fem |

Bevel gear stage

Calculation | Attribute |

|---|---|

Load capacity acc. to ISO 10300 (2023) | gta_switch_bevel_mesh_iso_10300 |

Load carrying capacity according to ISO 10300 (2014) | gta_switch_bevel_mesh_din_3991 |

Load capacity acc. to AGMA 2003-D19 | gta_switch_bevel_mesh_agma_2003_d19 |

Load carrying capacity according to AGMA (2003-C10) | gta_switch_bevel_mesh_agma_2003_c10 |

Load carrying capacity according to all current classification societies | gta_switch_bevel_mesh_all_classification_societies |

Load-free tooth contact simulation | gta_switch_bevel_mesh_local_tooth_contact |

Local stress calculation | gta_switch_bevel_mesh_local_loads |

Local load carrying capacity calculation | gta_switch_bevel_mesh_local_capacity |

Local damage accumulation | gta_switch_bevel_mesh_local_damage_accumulation |

Shaft

Calculation | Attribute |

|---|---|

Shaft safety according to DIN 743 (2012) | gta_switch_din_743 |

Strength verification according to FKM (2012) | gta_switch_fkm_2012 |

Bearings

Calculation | Attribute |

|---|---|

Rolling bearing service life | gta_switch_bearing_lifetime |

Plain bearing calculation (without iteration) | gta_switch_slide_bearing_with_linear_stiffness |

Plain bearing calculation (with iteration) | gta_switch_slide_bearing_with_iteration |

Shaft-hub connections

Calculation | Attribute |

|---|---|

Shaft-hub connection load carrying capacity | gta_switch_shaft_hub_connections |

Efficiency

Calculation | Attribute |

|---|---|

Power loss and heat management | gta_switch_power_loss |

Dynamics

Calculation | Attribute |

|---|---|

Eigenvalue/eigenmode calculations | switch_eigenvalue_calculation |

FEM

Calculation | Attribute |

|---|---|

Calculation of FEM component deformation | switch_calculation_fem_part_deformation |

Load spectra

Calculation | Attribute |

|---|---|

Consideration of load spectra | consider_spectrum |

Single component calculations

Example: calculate the bearing life for a single rolling bearing

1var bearingID = 10; 2runCalcMethod("800_ROLLING_BEARING_LIFETIME", bearingID);

Assigns the ID of the rolling bearing to the bearingID variable. | |

Performs the single component calculation with the "800_ROLLING_BEARING_LIFETIME" methodID. |

Tip

You can also specify only the method number "800" instead of the complete method ID "800_ROLLING_BEARING_LIFETIME."

Gear unit

Calculation | methodID |

|---|---|

Power flow | 010_POWER_FLOW |

Cylindrical gear stage

Calculation | methodID |

|---|---|

Main geometry | 100_DETAILED_MAIN_GEOMETRY |

Load carrying capacity acc. to ISO 6336 (2006) | 393_FVA241_ISO6336_2008 |

Load carrying capacity acc. to ISO 6336 (2019) | 394_FVA241_ISO6336_2019 |

Load carrying capacity acc. to DIN 3990 (1987) | 122_LOAD_CAPACITY_DIN_3990_1987 |

Load carrying capacity acc. to AGMA 2101 (D04) | 123_LOAD_CAPACITY_AGMA_2101_D04 |

Load carrying capacity acc. to VDI 2736 (2014) | 390_FVA241_VDI2736 |

Design calculation acc. to VDI 2736 (2014) | 391_FVA241_VDI2736_INITIAL_DESIGN |

Load carrying capacity according to all current classification societies | 140_LOAD_CAPACITY_CLASS_ALL |

Load carrying capacity acc. to ABS (2019) | 398_LOAD_CAPACITY_ABS_2019_part4 |

Load carrying capacity acc. to ABS (2011) | 131_LOAD_CAPACITY_CLASS_ABS_2011 |

Load carrying capacity acc. to BV (2010) | 133_LOAD_CAPACITY_CLASS_BV_2010 |

Load carrying capacity acc. to CCS (1996) | 134_LOAD_CAPACITY_CLASS_CCS_1996 |

Load carrying capacity acc. to DNV (2012) | 141_LOAD_CAPACITY_CLASS_DNV_2012 |

Load carrying capacity acc. to GL (1998-2006) | 136_LOAD_CAPACITY_CLASS_GL_1998 |

Load carrying capacity acc. to LRS (2019) | 397_LOAD_CAPACITY_LRS_2019_part5 |

Load carrying capacity acc. to LRS (1990-2006) | 137_LOAD_CAPACITY_CLASS_LRS_1990 |

Load carrying capacity acc. to RINA (2004-2006) | 138_LOAD_CAPACITY_CLASS_RINA_2004 |

Load carrying capacity acc. to RMS (2005-2010) | 139_LOAD_CAPACITY_CLASS_RMS_2005 |

Load carrying capacity acc. to ABS (1997) | 151_LOAD_CAPACITY_OLD_ABS_1997 |

Load carrying capacity acc. to ABS (1980) | 152_LOAD_CAPACITY_OLD_ABS_1979 |

Load carrying capacity acc. to AGMA 2101 (C95) | 124_LOAD_CAPACITY_AGMA_2101_C95 |

Load carrying capacity acc. to AGMA 2001 (C95) | 167_LOAD_CAPACITY_AGMA_2001_C95 |

Load carrying capacity acc. to AGMA 2001 (B88) | 153_LOAD_CAPACITY_OLD_AGMA_2001_B88 |

Load carrying capacity acc. to AGMA 421.06 (1969) | 154_LOAD_CAPACITY_OLD_AGMA_421_1969 |

Load carrying capacity acc. to AGMA 210.02 (1965/66) | 155_LOAD_CAPACITY_OLD_AGMA_210_1965 |

Load carrying capacity acc. to BS 436 (1940) | 156_LOAD_CAPACITY_OLD_BS_436_1940 |

Load carrying capacity acc. to BV (2003/2006) | 157_LOAD_CAPACITY_OLD_BV_2001 |

Load carrying capacity acc. to BV (1977) | 158_LOAD_CAPACITY_OLD_BV_1977 |

Load carrying capacity acc. to DNV (2003) | 135_LOAD_CAPACITY_CLASS_DNV_2003 |

Load carrying capacity acc. to DNV (1990/1993) | 159_LOAD_CAPACITY_OLD_DNV_1993 |

Load carrying capacity acc. to DNV (1978) | 160_LOAD_CAPACITY_OLD_DNV_1978 |

Load carrying capacity acc. to DIN (1970) | 161_LOAD_CAPACITY_OLD_DIN_1970 |

Load carrying capacity acc. to GL (1980) | 162_LOAD_CAPACITY_OLD_GL_1980 |

Load carrying capacity acc. to Henriot (1976) | 163_LOAD_CAPACITY_OLD_HENRIOT_1976 |

Load carrying capacity acc. to ISO 6336 (1996) | 168_LOAD_CAPACITY_OLD_ISO_6336_1996 |

Load carrying capacity acc. to ISO 6336 (2006) - STplus | 121_LOAD_CAPACITY_ISO_6336_2006 |

Load carrying capacity acc. to Niemann (1965) | 164_LOAD_CAPACITY_OLD_Niemann_1965 |

Load carrying capacity acc. to LRS (1978) | 165_LOAD_CAPACITY_OLD_LRS_1978 |

Load carrying capacity acc. to RINA (1982) | 166_LOAD_CAPACITY_OLD_RINA_1982 |

Load distribution (FEM) - without environment | 310_LOAD_DISTRIBUTION_STIRAK |

Wear calculation (FEM) - without Environment | 312_STIRAK_WEAR |

Dynamic Rollover (FEM) - without Environment | 320_TRANSIENT_NONLINEAR_FEM_SOLVER |

Bevel gear stages

Calculation | methodID |

|---|---|

Geometry Design Acc. to ISO 23509 (2016) | MODEL_METHOD_BEVEL_MESH_GEOCALCULATION |

Load carrying capacity acc. to ISO 10300 (2014) | 715_BEVEL_STANDARD_ISO_10300_2014 |

Load carrying capacity acc. to AGMA (2003-C10) | 735_BEVEL_STANDARD_AGMA_2003_C10 |

Load carrying capacity acc. to American Bureau of Shipping (2016) | 759_BEVEL_STANDARD_ABS_2016 |

Load carrying capacity acc. to Bureau Veritas (2014) | 758_BEVEL_STANDARD_BV_2014 |

Load carrying capacity acc. to CCS (2015) | 742_BEVEL_STANDARD_CCS_2015 |

Load carrying capacity acc. to DNV / GL (2015) | 757_BEVEL_STANDARD_DNV_2015 |

Load carrying capacity acc. to Lloyd’s Register (2015) | 756_BEVEL_STANDARD_LR_2015 |

Load carrying capacity acc. to RS (2017) | 741_BEVEL_STANDARD_RS_2017 |

Load carrying capacity according to all current classification societies | 760_BEVEL_STANDARD_CLASS_ALL |

Load carrying capacity acc. to ISO 10300, DIN 3991, FVA 411 | 710_BEVEL_STANDARD_ISO_10300_2001 |

Load carrying capacity acc. to AGMA (2003-B97) | 730_BEVEL_STANDARD_AGMA_2003_B97 |

Load carrying capacity acc. to AGMA (2003-A86) | 751_BEVEL_STANDARD_AGMA_2003_A86 |

Load carrying capacity acc. to DNV (2003) | 752_BEVEL_STANDARD_DNV_2003 |

Load carrying capacity acc. to DNV (1993) | 753_BEVEL_STANDARD_DNV_1993 |

Load carrying capacity acc. to GL (1998) | 754_BEVEL_STANDARD_GL_1998 |

Load carrying capacity acc. to LR (1998) | 755_BEVEL_STANDARD_LR_1998 |

Load Capacity - all current classification societies | 760_BEVEL_STANDARD_CLASS_ALL |

Load-free tooth contact simulation | 761_BEVEL_NO_LOAD_CONTACT |

Local stress calculation | 762_BEVEL_LOCAL_STRESS |

Local load carrying capacity calculation | 763_BEVEL_LOCAL_CAPACITY |

Local damage simulation | 770_BEVEL_LOCAL_DAMAGE_SIMULATION |

Local damage accumulation | 764_BEVEL_LOCAL_DAMAGE |

Variational calculations | 765_BEVEL_VARIATIONS |

Crossed helical and worm stages

Calculation | methodID |

|---|---|

Worm gear standard load capacity | 1401_WORM_GEAR_PAIR_CAPACITY |

Worm gear load distribution and contact pattern | 1402_WORM_GEAR_PAIR_CONTACT_PATTERN |

Worm gear contact lines and physical characteristics | 1403_WORM_GEAR_PAIR_CONTACT_VALUES |

Worm gear self-braking | 1405_WORM_GEAR_PAIR_SELF_LOCKING |

Worm gear starting efficiency | 1406_WORM_GEAR_PAIR_STARTING_FRICTION |

Crossed helical geometry and load capacity | 1501_CROSS_HELICAL_STAGE_LOAD_CAPACITY |

Shafts and bearings

Calculation | methodID |

|---|---|

Shaft load capacity in notch area (DIN 743 + FVA 700) | 1800_NOTCH_STANDARD |

Shaft load capacity in notch area (FKM 2012 local) | 1801_NOTCH_FKM_2012_LOCAL |

Rolling bearing calculations | 800_ROLLING_BEARING_LIFETIME |

Journal bearing simulation | 650_SLIDE_BEARING_CALCULATION_WITH_COMBROS |

Axial sliding bearing simulation | 1600_AXIAL_SLIDE_BEARING_CALCULATION |

Shaft-hub connections

Calculation | methodID |

|---|---|

Multiple interference fit load capacity (interference specified) | 1000_MULTIPLE_INTERFERENCE_FIT_UEBERMASS NoteThe combo attribute "calculation_process_multiple_interference_fit" can be used to specify which calculation variant is to be executed:

|

Cylindrical interference fit load capacity acc. to DIN 7190 and Kollmann | 1100_CYLINDRICAL_INTERFERENCE_FIT_DIN_7190 |

Tapered interference fit load capacity acc. to DIN 7190 | 1200_CONE_INTERFERENCE_FIT_DIN_7190 |

Feather key load capacity acc. to DIN 6892 | 1300_FEATHER_KEY |

Spline gear geometry | 2100_SPLINE_GEOMETRY |

Spline gear load capacity acc. to | 2101_SPLINE_LOAD_CAPACITY |

Bolted joints

Calculation | methodID |

|---|---|

Bolt pre-dimensioning according to VDI 2230 (2015) | 399_VDI_2230 |

Bolt calculation according to VDI 2230 (2015) | 395_VDI_2230 |

Multi bolt calculation according to VDI 2230 (2014) | 392_VDI_2230 |

Additional

Calculation | methodID |

|---|---|

Lubricant network oil distribution | 2001_LUBRICANT_NETWORK |