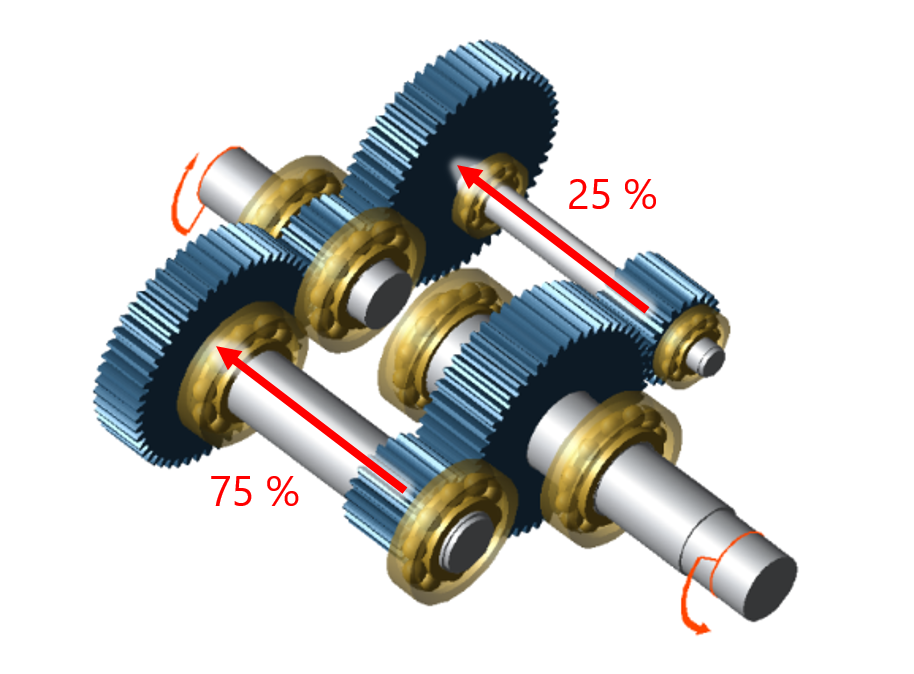

Power Splitting

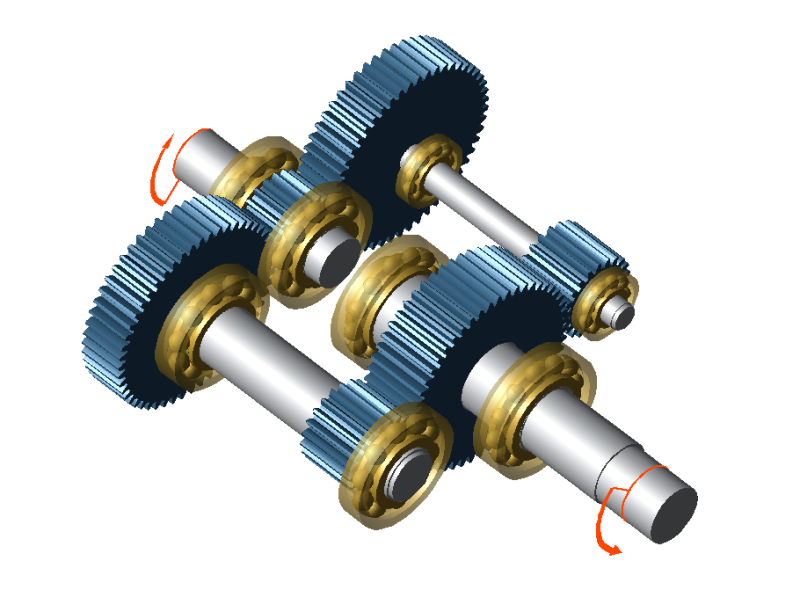

This tutorial will demonstrate power splitting and the associated settings. Power splitting makes it possible to divide the power flow between multiple parallel shafts.

The following files are required to follow along with this tutorial in the FVA-Workbench:

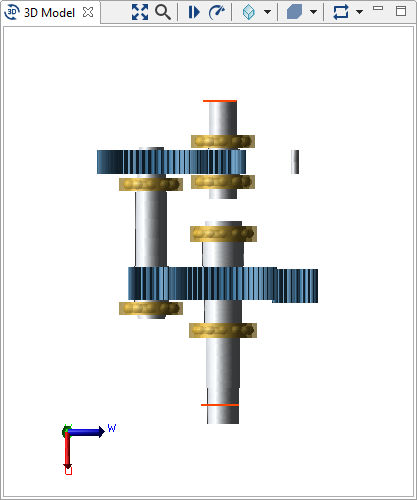

Modeling

Load the power_split.wbpz gearbox model:

Project -> Open

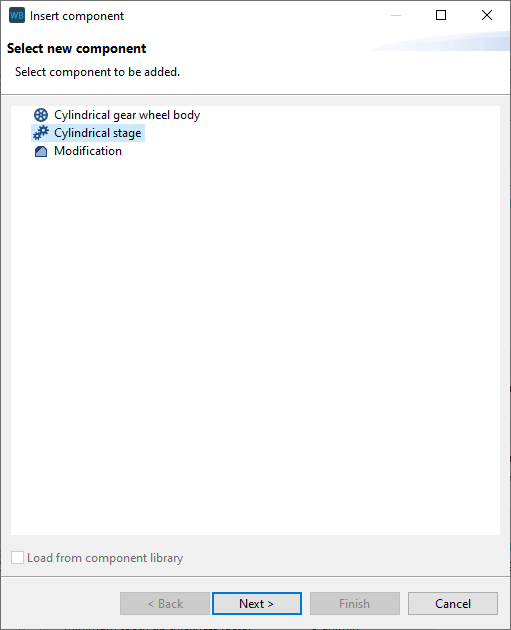

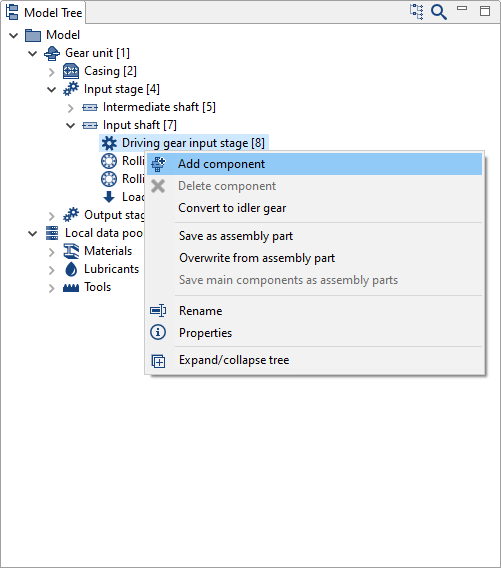

Add a cylindrical stage

Right click "Driving gear input stage [8]" in the Model Tree and add a new cylindrical stage component.

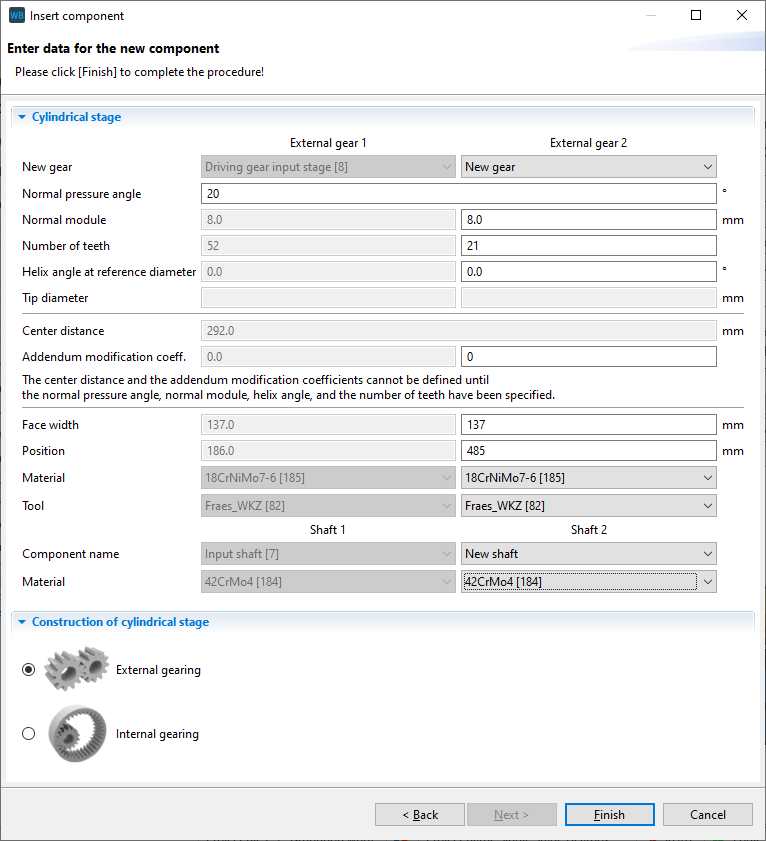

Specify the gear data

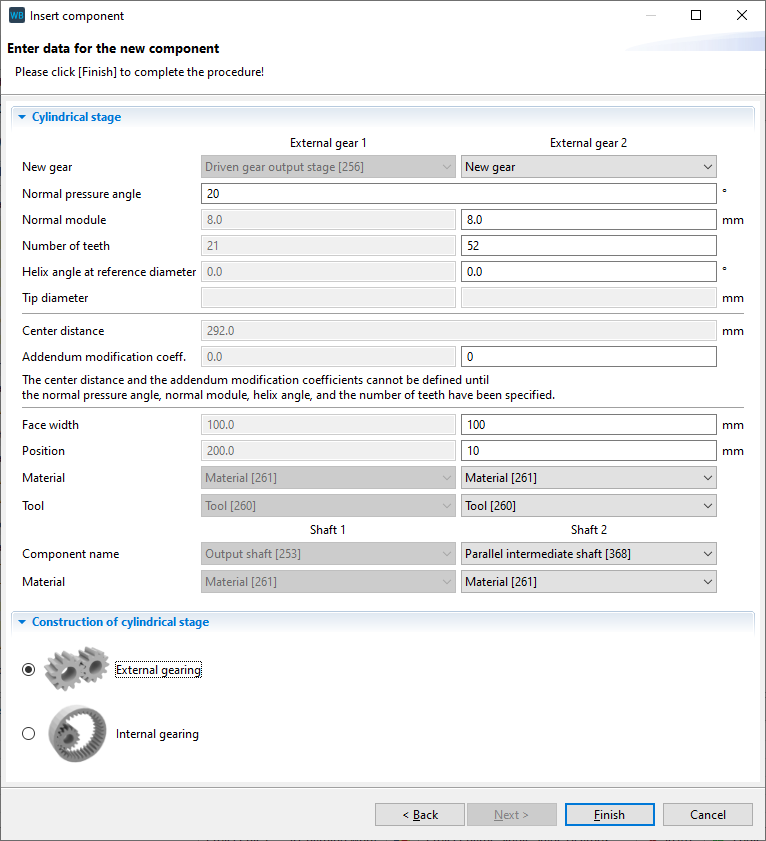

Enter the gear and material data in the wizard as shown in the image below.

Select "new shaft" for Shaft 2. A new shaft and gear will be created. This shaft is not yet positioned and does not have any contours.

Right-click on the new shaft in the Model Tree and rename it to "parallel intermediate shaft."

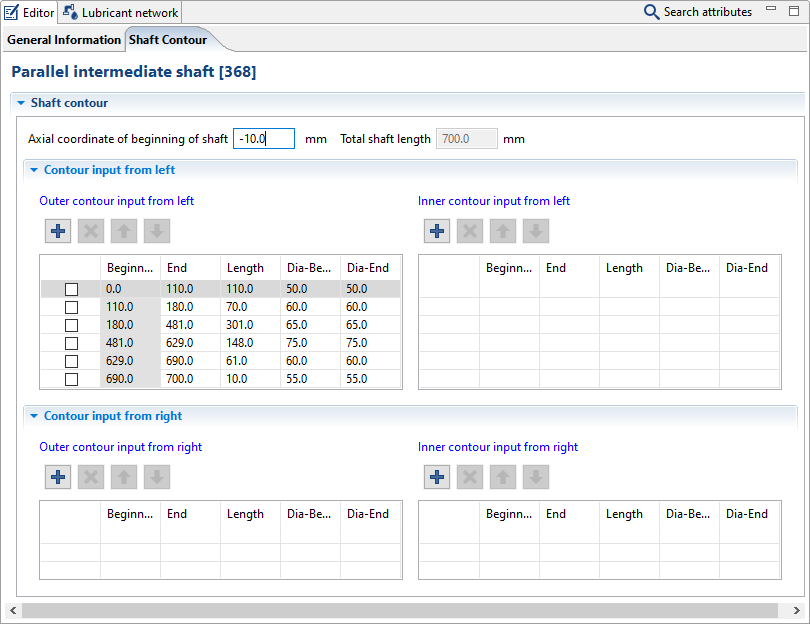

Adjust the shaft position and contour

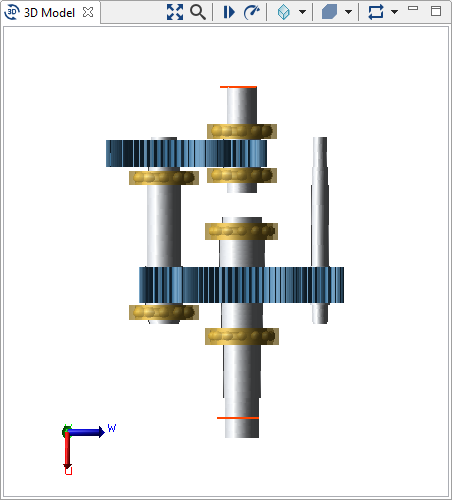

Select "Parallel intermediate shaft [368]" in the Model Tree and switch to the Shaft Contour tab in the Editor. Now, add new shaft sections and change the diameters and lengths as shown in the image below. Enter -10 for the axial coordinate of the beginning of the shaft.

Add a cylindrical stage

Right-click "Driven gear output stage [256]" in the Model Tree, create a new cylindrical stage, and enter the gear data as shown in the image below.

Select "parallel intermediate shaft" as the shaft for the new gear.

Add rolling bearings

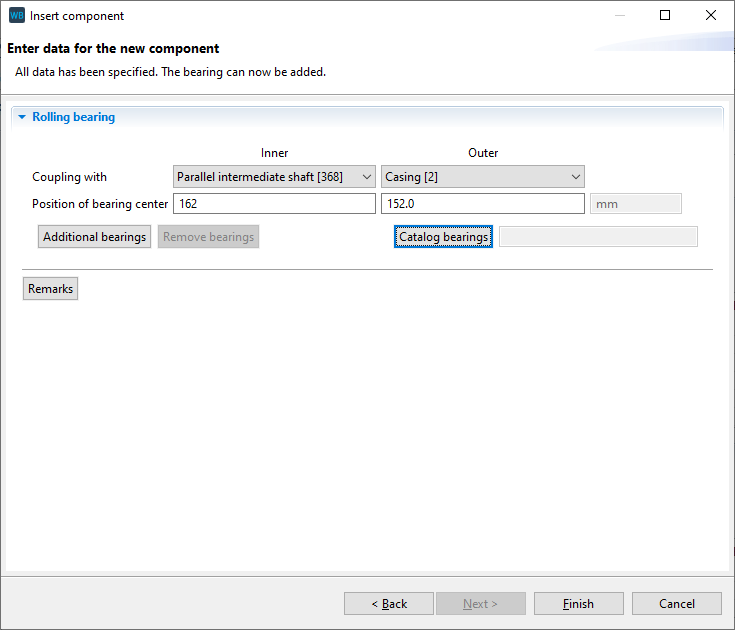

Right-click "Parallel intermediate shaft [368]" in the Model Tree and add a new rolling bearing component.

Couple the inner ring with "parallel intermediate shaft" and the outer ring with the casing. Specify 162mm as the position of the bearing center of inner ring.

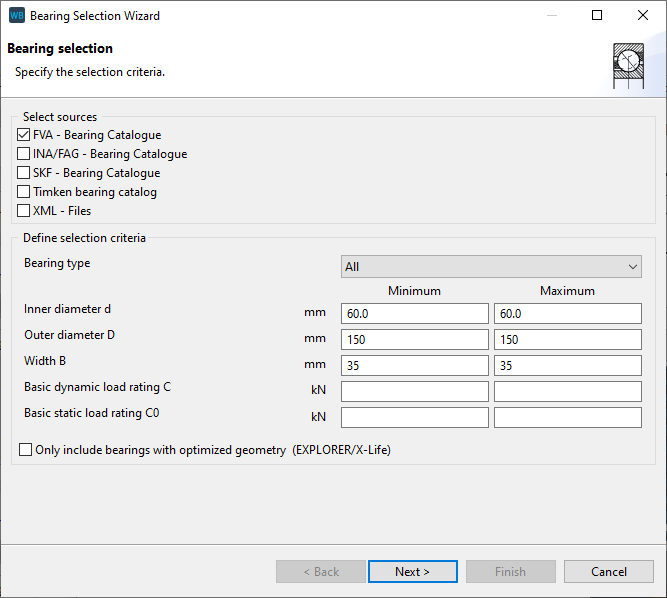

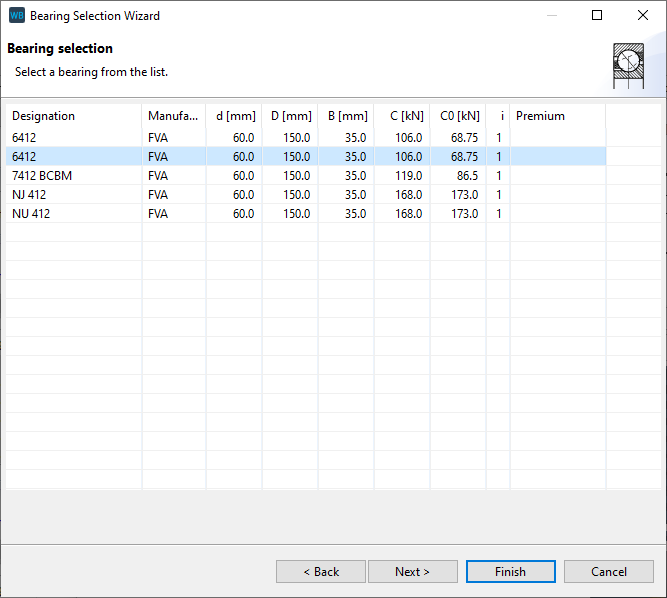

Now, click "catalog bearings" and enter the search criteria as shown below.

Select bearing 6412 and click "Finish."

Add another rolling bearing

Now add a second, identical bearing on the shaft and repeat Step 6. Enter 645mm for the position of the inner ring of this bearing.

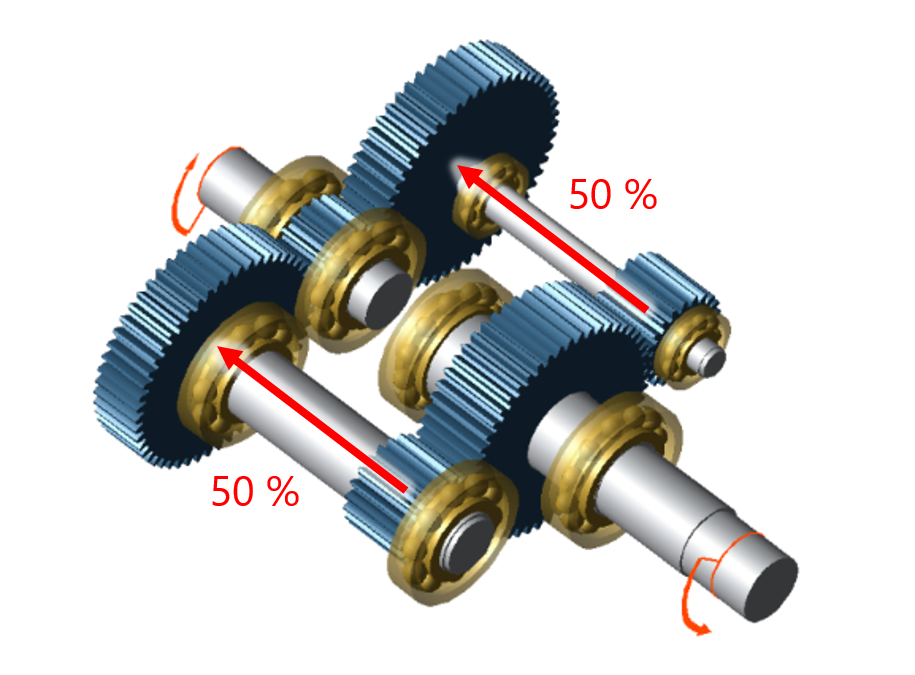

Define the power flow

Power splitting can be defined in two ways in the FVA-Workbench:

Uniform power distribution across the power paths | Power splitting depending on the gearbox stiffness |

This is the standard option which will automatically be used during the system calculation. The load is transferred evenly across the stages. | This calculation must be specifically activated. Select the Gear Unit in the Model Tree, switch to the Control Parameters tab, and select the checkbox for "Consider resulting torques from the system calculation instead of nominal torques." |

|  |

Each of the two power paths transmits exactly 50% of the power. |  The power path with the stiffer, more rigid shaft transmits significantly more power. |